At the beginning of summer, I reviewed a book called The Science of Cheese for American Scientist Magazine. Last week, with summer winding down, the review was published [1] in the midst of a spate of cheese-related activity in my life: I received an invitation to the christening of a local cheese cave [2], I registered for a raw milk cheese tasting class, and my all-time favorite cheese, aged gouda, went on sale.

At the beginning of summer, I reviewed a book called The Science of Cheese for American Scientist Magazine. Last week, with summer winding down, the review was published [1] in the midst of a spate of cheese-related activity in my life: I received an invitation to the christening of a local cheese cave [2], I registered for a raw milk cheese tasting class, and my all-time favorite cheese, aged gouda, went on sale.

Reading The Science of Cheese made me consider the range of products that pass for cheese. To some, cheese means a fat quesadilla oozing with melted cheddar jack. To my aunt, cheese is a mail-order box lined with freezer packs from Murray’s in New York City. My cheese history starts with slices of American (which I still love) and progresses to my beloved aged gouda.

Mary Turner, former cheese-maker at Celebrity Dairy in Siler City, NC, pours pasteurized goat milk into the cheese-making vat.

North Carolina has a growing number of cheese-makers. I’ve visited dairy farms and cheese houses, so I know for sure that some cheese is made in small batches and monitored daily by actual people. But there are missing connections. If a cheese comes all the way from France, and it’s sold regularly in the fancy cheese case at my market, surely it’s being produced in bigger batches and sold elsewhere, right? Can good cheese be made in bigger batches? Where are the lines drawn?

So when I picked up The Science of Cheese, I hoped to read about the quaint cheese-making ventures that somehow keep us all well-stocked. I also hoped to learn about massive cheese-making facilities and how they make the dull bricks that pass as cheese in mainstream supermarkets. The book fell open to the back flap; the author looked a lot like my p-chem professor, and his bio described him as “creating new dairy products” and “expanding marketability.”

I actually dressed as cheese one Halloween. The costume had formerly been a book for a Harry Potter release party.

I recoiled in horror; this didn’t sound like my kind of cheese! Then followed an anguished evening of wondering how to reconcile my art half and my science half with thoughts like, “Science is the truth! But I’m swayed by the appealing nature of the phony pastoral setting! I’m a terrible scientist!” and even “Maybe cheese is a metaphor for me: part art and part science….” But anyway, I eventually started reading.

Although The Science of Cheese was informative and entertaining, it didn’t provide the answers I craved. As described in my review, I found a brief description of how tasteless, made-in-America cheese has had its fat and protein replaced with water and its aging time reduced (to save money). But I still lacked a big picture understanding.

Then I went to cheese class.

The class was led by Ashley Morton and Tyler Morgan, who recently flew to California to take the American Cheese Society’s Certified Cheese Professional Exam. [3] They had prepared plates for each student with eight wedges of cheese on each, and they described each as we ate it. Here are some of the things I learned:

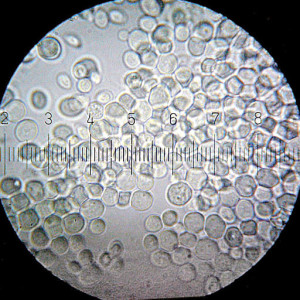

- The sources of the microflora that affect raw milk cheese are the milk itself, the added starter culture, and the environment. When milk is pasteurized (heated), the milk microflora are lost.

- When milk is pasteurized, the proteins denature, which results in a more pliant cheese that is harder to crumble or break. (Tyler used the word plasticky, for lack of a better word, but plastic has a science-y meaning of “the opposite of elastic.”)

- The properties of a raw milk cheese vary more than those of cheeses made with pasteurized milk. An artisan cheese-maker enjoys this inconsistency and monitors the cheeses daily, but in a larger production facility, consistency is important.

- The Kinsman Ridge cheese that we tasted had a white color because it was made with milk from April, when the cows (in Jasper Hill, VT) had not been on pasture all winter. The milk from the summertime produces a yellower cheese. This is true of cow’s milk but not of sheep or goat milk because those animals can process the beta carotene that causes the color.

- The rind that forms on raw milk cheese varies depending on where the cheese is aged because of different microflora in the air. This is an example of terroir, the characteristics brought to cheese by its environment. In The Science of Cheese, the author describes terroir as a disputed concept that some scientists say has only negligible effects; I wondered how they might explain the different rinds.

- There was a question about the crystals sometimes found in cheese. According to the Internet, these crystals can be calcium lactate that crystallizes out of solution as the cheese dries out. They can also be amino acid crystals that form as the casein proteins unravel during aging. (Incidentally, I also discovered that these crystals stimulate stuff that leads to happiness. [4] No wonder I like that aged gouda so much!)

- Herve Mons is a famous affineur in France who ages 200 types of cheese in cheese caves built inside an abandoned train tunnel. (You can see a slideshow of the tunnel here, and it’s not nearly as dank and creepy as you’d expect. [5]) Some farmers age their own cheeses, but some make the cheese and sell it to an affineur. The farmer makes less money but doesn’t have to spend time on the aging process or take the inherent risks.

- The blue in blue cheese forms when the cheese is pierced to let in oxygen, which enables the blue mold to grow. The sizes and locations of the blue spots can therefore be controlled.

- Blue cheeses that are “naturally fused” end up very crumbly, whereas blue cheeses that are pressed end up with more of a creamy texture.

Tyler took a moment to share his thoughts on the FDA’s aggressive stance towards raw milk cheeses. In June, an FDA inspector cited some cheese-makers for aging on wooden boards, saying the boards could not be properly sanitized according to FDA specifications. [6] The cheese-making community responded, and the FDA quickly put out a statement that said (I’m paraphrasing) “Oh, no, no, we didn’t mean that!” [7] Now, the FDA has lowered the acceptable level of E. coli in cheese from 10,000 to 10, in spite of the fact that many strains of E. coli are nonpathogenic and are in fact a healthy part of the microflora of the gut. It seems the FDA is not using actual science to make safety rules.

At this point, I was filled with cheese and beer and was dying to say something about the Cheese Nun, but I couldn’t remember her story well enough. What I remembered was that when traditional cheese-making at a cloister in Connecticut came under fire by government regulators, one of the sisters went to university to receive a doctorate in microbiology so that she could properly defend cheese-making at the cloister. Upon googling, I now remember that she did an experiment for inspectors in which she added E. coli to batches of cheese in wooden and stainless steel vats. (The inspectors had been upset by the use of wood.) The wooden vat ended up with no E. coli, whereas the cheese in the sterile stainless steel vat was filled. The nun, Sister Noella Marcellino, was the subject of a PBS documentary and was included in Michael Pollan’s book Cooked.

Cheese class was wrapping up, and I felt clearer on the whole state of cheese. It’s not an A or B situation but a wide range of possibilities, from farmers who make their own to cheese-makers who buy local milk, to affineurs who age the cheese of others, to larger batches of cheese that are kept consistent, all the way down to Easy Cheese and Cheez Whiz. Tyler not only sent me a photo from class but graciously gave me another book to read: Cheese and Culture by Paul S. Kindstedt, which is sure to lend more insight.

[1] Buehler, Emily. ”The Cheese Plate Stands Alone,” American Scientist, Sept-Oct 2014. https://www.americanscientist.org/bookshelf/pub/the-cheese-plate-stands-alone

[2] A slideshow of the construction of the cheese cave at Piemonte Farm in Burlington, NC. http://www.piemontecheese.com/cheese-cave.html

[3] About the ACS CCP exam. http://www.cheesesociety.org/events-education/certification-2/

[4] “Why Aged Cheeses Are Crunchy—And Why They Make You Happy.” Savenor’s. March 11, 2013. http://www.savenorsmarket.com/web/news/why-aged-cheeses-are-crunchy-and-why-they-make-you-happy/

[5] Slideshow of Herve Mons’s train tunnel. http://www.mons-fromages.com/sites/default/files/depliant-tunnel-gb/index.html

[6] I think this is the inspector’s statement; I couldn’t find a version on the FDA website: http://www.foodsafetynews.com/files/2014/06/Use-of-wooden-shelves-for-cheese-aging.pdf. And this is the code to which she refers, Code of Federal Regulations Title 21, section 110.40(a): http://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm?fr=110.40

[7] “Clarification on Using Wood Shelving in Artisanal Cheesemaking.” CFSAN Constituent Update. June 11, 2014. http://www.fda.gov/Food/NewsEvents/ConstituentUpdates/ucm400808.htm