Last April at the Asheville Bread Festival, I heard Dominique Homo from LaSaffre talk on “The Science of Yeast.” I’ve meant to type up my notes ever since, so here they are.

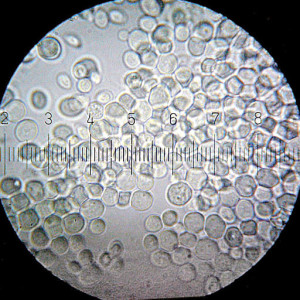

Baker’s yeast under a microscope (100× objective, 15× eyepiece; numbered ticks are 11 µm apart). By Bob Blaylock, via Wikimedia Commons.

First off, I was embarrassingly late to the talk because of my own class. I arrived during a description of the yeast budding process, which occurs every 20 minutes under controlled conditions including a temperature of 28° (I assume °C) and regulated pH and air flow. Note that this temperature works well for growing yeast but is too high for dough.

Others points of interest on growing yeast:

- Traditionally, molasses was used as the platform on which yeast was grown. But the sugar industry has become more developed in America; there is now only about 45% of sugar left in molasses, as opposed to 60% in Cuba. (I don’t know if he meant that 45% of the total sugar remains or that 45% of the molasses is sugar.) Therefore, corn syrup is now used.

- The yeast-growing process starts with yeast from a yeast bank that is sent frozen by mail. It is grown on pure glucose for three days in a sterile environment. Then it goes into a tank. What starts as less than a gram of yeast becomes about 250 tons in 10 days.

- Dominique said something interesting about periodically “removing the new yeast” to “control mutations,” but I didn’t catch it. I think he meant that they want as much of the yeast as possible to come from reproduction of the original, pure yeast cells. If a mutation does occur, it will propagate (kind of like when you play Telephone), so removing newer yeast cells reduces the chances of that occurring. This also means a reduction in yeast production, but maybe 250 tons is plenty.

Next, Dominique spoke about the types of yeast. There were a few kinds I had never heard of. Here’s a table:

-

- Cream yeast. This is 80% water and 20% yeast. It is used by large bakeries (25,000 lbs/week!) and is delivered to the bakeries in tanker trucks. Yikes.

-

- Crumbled yeast. This is fresh yeast that is crumbled and packaged in 50 lb bags for medium-sized bakeries.

- Compressed yeast. A.k.a. fresh yeast, this comes in one pound blocks and is used by medium- and small-sized bakeries. It is often two to three weeks old by the time it arrives, so you should only use it if you can use it up quickly.

- Active dry yeast. This is a dried-out version of yeast that has a much longer shelf-life. Supposedly, it must be activated before use (more on this below). It is used by small bakeries, artisan bakeries, and home bakers. Some of the yeast cells are dead. This can affect dough in ways that some prefer and some don’t; more on this below.

- Instant yeast. This is also a dried yeast used by small bakeries, artisan bakeries, and home bakers, but it does not need to be activated before adding to dough. Instant yeast is actually drier than active dry yeast! A different drying process is used that enables it to dry very quickly so that yeast cells are not killed: The yeast is made into very thin noodles with a yeast version of a spaghetti machine. The noodles exit the machine into blowing hot air, which dries them and causes them to break. (If you look closely at the yeast, it has a tubular shape.) The yeast is then vacuum-packed.

- Deactivated yeast. This is dead yeast. Huh? Why would anyone add that to bread dough? The answer deserves a new paragraph.

Deactivated yeast is made by heating cream yeast on a hot plate until it is dead. It contributes no fermentation to the dough but “enhances the yeasty flavor profile.” It also provides “better machinability” by releasing a molecule (glutathione) that reacts with the protein in the dough. (It is a reducing reaction.) The reaction makes the dough less elastic and more extensible, which means you can mix it less. This yeast is often used in doughs that need to be stretched such as in pizza, croissants (which are folded repeatedly as layers of butter are added—the dead yeast reduces the time needed for the dough to relax between folds), and puff pastry as well as for crackers (it enhances the cheesy flavor). It is also used when consistency is needed in a large number of loaves, for example, 5000 baguettes are being made per hour and each one needs to be 5 inches long, not 4.9. Similar effects are obtained with L-cysteine, but deactivated yeast looks “cleaner” in an ingredient list because it can be called “yeast.”

Some people like active dry yeast because it contains some dead yeast; it can produce a reduced version (ha ha, bad chemistry pun) of the effects of deactivated yeast.

Now we come to activating. Ah, activating! I had just told my class all about why to skip activating, so I cowered lower in my seat as Dominique espoused its necessity. Dominique said that it takes yeast a long time to get going in flour; it needs to rehydrate and dissolve. If the water needed by the recipe is too cold for the yeast, the yeast won’t work, and some of it will die, resulting in a slow fermentation. The yeast needs to be rehydrated with 100 to 110° water (I assume °F).

The reason I don’t like activating, aside from it being a slight pain, is that you need to use some water, which you must subtract from your recipe. With students who aren’t experienced with recipes, this can cause confusion; and if the recipe is not adjusted, the hydration becomes off and the dough is too wet. I always tell students to mix the yeast into their flour, which will protect it if cold water is used. (Incidentally, the way I came to this practice was that I was doing it with “instant yeast” that turned out to be mislabeled active dry yeast, and I never had a problem.)

But I wouldn’t presume to contradict the yeast expert. Now it occurred to me, however, that I always use an autolease when I make bread and teach classes. Maybe this rest period gives the yeast a chance to activate before kneading begins, and this is why I’ve never had a problem.

Dominique compared LeSaffre’s gold and red yeasts. (The names refer to the package colors.) The gold is osmotolerant yeast, which is designed to work with doughs that use more than 5% sugar. Why this works deserves its own blog post, so I’ll get right on that. (Update: Read it here.) Dominique also mentioned that the gold yeast works better with low hydration doughs and produces a more evenly browned crust, whereas the red yeast results in more burn spots on bread. I’m not sure why this happens, but I will post about it if I ever learn more.

Dominique concluded by remarking that people often blame the yeast for problems with their bread-making even while using improper procedures and taking short-cuts. The yeast is rarely at fault! For example, he consulted with a bakery at a grocery store that was not getting good rise and discovered that they were baking everything (not just pastries but breads) at a low temperature of 350° to make it easy on their staff.

Other notes I scribbled down, with no further explanation:

- You can spike sourdough with up to 0.1% yeast and it won’t affect the flavor.

- Hard water affects yeast.

- Chlorine in water slows yeast.

- Do not use distilled water to make bread.

- Citric acid is really bad.

The deactivated yeast is fascinating. I’d never heard of it before, but it does sound useful.

Thank you for the informative post. I have been using instant yeast for some time now. Beats compressed and dry yeast both on the results count and the convenience count. I live in India and ambient temperatures are in 90-100 F range. Instant yeast can keep in the refrigerator for almost two years. Compressed yeast at best lasts a month or so.

I’m glad you are able to get instant yeast. Sometimes it is still hard to find in stores in the U.S.!

Any reason that distilled water is bad for bread making?

Hi Sarah, I’ve read that hard or soft water from your tap can bring problems to bread making. Distilled water has had minerals removed, in addition to the nasty stuff like chlorine, and this makes it akin to soft tap water. So, it might not work well in bread. There is a thorough explanation here: http://www.elclubdelpan.com/en/master_book/water-functions-baking

I hope that helps!